What do you think a counterweight does for a mine winding system?

A counterweight in a mine winding system plays a pivotal and often underappreciated role in the safe and efficient operation of mining activities. The mine winding system, consisting of shafts, cages, ropes, and other components, is used to transport personnel and materials up and down the mine. Here, the inclusion of a counterweight helps balance forces, reduce energy consumption, increase system safety, and enhance overall efficiency. This article explores the critical functions of a counterweight in a mine winding system, focusing on the South African mining context, where this technology is widely applied.

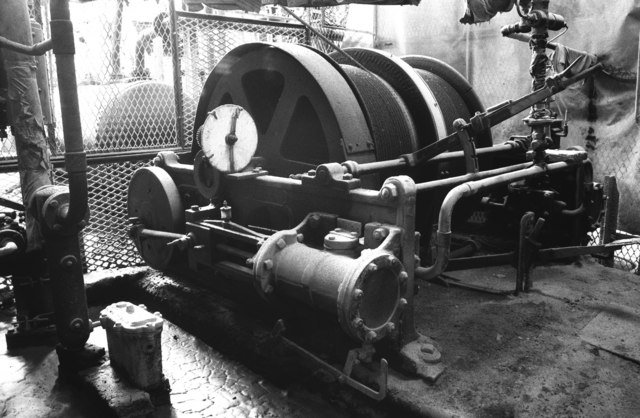

What a Counterweight Does for a Mine Winding System

A counterweight in a mine winding system serves several critical functions that contribute to the overall safety and efficiency of mining operations. It balances the forces within the system, ensuring equilibrium and stabilisation, which helps in reducing stress on ropes and other components, as well as minimising vibrations for smoother operation. This balance achieved by the counterweight also leads to a reduction in energy consumption, making the operation more energy-efficient and cost-effective, particularly relevant in energy-intensive mining activities. Furthermore, the counterweight plays a vital role in enhancing safety by preventing mechanical failures and ensuring compliance with strict safety regulations. In the context of South African mines, the application of counterweights in mine winding systems is integral to maintaining safety standards and operational efficiency, reflecting a complex interplay of physics and engineering.

Balancing Forces

The primary function of a counterweight is to balance the forces within the system, ensuring smooth and stable operation.

- Stabilisation of the System: By offsetting the weight of the load in one cage with a counterweight on the opposite side, the system’s equilibrium is maintained. This helps in reducing stress on the ropes and other structural components.

- Reduction of Vibrations: Balancing the forces minimises vibrations and oscillations, resulting in smoother operation and less wear and tear on the machinery.

- Example in South African Context: In many South African mines, counterweights are precisely calculated and applied to optimise the load balance, catering to the specific geological and operational conditions of each mine.

Energy Efficiency

The implementation of a counterweight also contributes significantly to energy efficiency.

- Reduction of Energy Consumption: By balancing the weight on both sides of the winding system, the motor doesn’t have to work as hard to lift or lower the cages, thereby consuming less energy.

- Cost-Effectiveness: Energy efficiency translates into cost savings, reducing the operational costs of mining, which can be substantial, especially in energy-intensive mining activities in South Africa.

Safety Enhancement

Safety is paramount in mining, and the counterweight plays a vital role in this aspect.

- Prevention of Mechanical Failures: By evenly distributing forces and reducing stress on components, the counterweight minimises the risk of mechanical failures that could lead to catastrophic accidents.

- Compliance with Safety Regulations: South African mining regulations emphasise the importance of safety, and the proper use of counterweights is aligned with these standards, ensuring adherence to safety protocols and legal requirements.

Conclusion

A counterweight in a mine winding system is far more than a mere balancing mechanism; it is a multifaceted component that greatly enhances the efficiency, safety, and cost-effectiveness of mining operations. Its role in stabilising the system, reducing vibrations, improving energy efficiency, and enhancing safety is vital for the robust performance of mining activities. In the context of South African mines, where mining is a significant part of the economy and where safety regulations are stringent, the effective use of counterweights in mine winding systems is an essential practice. This seemingly simple technology embodies a complex interplay of physics, engineering, and practical application, contributing to the sustainable and responsible mining that underpins much of South Africa’s industrial success.