Question: List any two products that have been treated in an electrolyte solution and galvanised.

let’s expand on the two examples of products that have undergone treatment in an electrolyte solution and galvanization to enhance their corrosion resistance and durability.

Automotive Parts

The Need for Treatment

Cars are subject to a variety of environmental stressors that can easily lead to corrosion of metal parts. From exposure to rain and snow to the corrosive effect of road salts, automotive parts must withstand a lot.

The Process

Galvanization for automotive parts is generally done by immersing them in a bath of molten zinc, a process known as hot-dip galvanizing. Some automotive manufacturers also employ electro-galvanizing, where parts are submerged in an electrolyte solution and a zinc coating is applied via electrical current.

Benefits

Both hot-dip and electro-galvanizing provide a protective barrier against corrosion. Zinc acts sacrificially; it corrodes before the underlying metal does, providing long-lasting protection. This enhances the lifespan of automotive parts, reducing the frequency and cost of repairs or replacements.

Real-world Application

Brands like Ford and Toyota often galvanize certain parts of their vehicles to ensure longevity. For instance, exhaust systems, chassis components, and body panels may be galvanized.

Outdoor Railings and Fences

The Need for Treatment

Outdoor railings and fences are constantly exposed to the elements, including rain, humidity, and fluctuating temperatures, all of which can accelerate rust and corrosion.

The Process

Hot-dip galvanizing is often used for these large structures. The railings or fences are dipped into a vat of molten zinc to create a corrosion-resistant coating. Electro-galvanizing, while less common for large structures, is sometimes used for smaller components like brackets and screws.

Benefits

The zinc coating acts as a protective layer, effectively sealing the metal from environmental exposure. This makes the railings and fences more durable, extending their functional life and maintaining their appearance.

Real-world Application

Public parks, residential areas, and even commercial spaces often employ galvanized railings and fences. For example, in oceanfront properties, galvanized steel is commonly used to resist the corrosive effects of saltwater.

Through these treatments, both automotive parts and outdoor railings and fences are better equipped to resist corrosion, thus extending their utility and minimizing maintenance costs. The processes of hot-dip galvanizing and electro-galvanizing play crucial roles in enhancing the durability and longevity of these products.

More Examples

Here’s a list of 15 additional products that are often treated in an electrolyte solution or galvanized to improve their corrosion resistance:

- Street Lamps: The poles are galvanized to withstand weather conditions and prevent rusting.

- Bicycle Racks: Galvanizing protects them from the elements, particularly in outdoor settings.

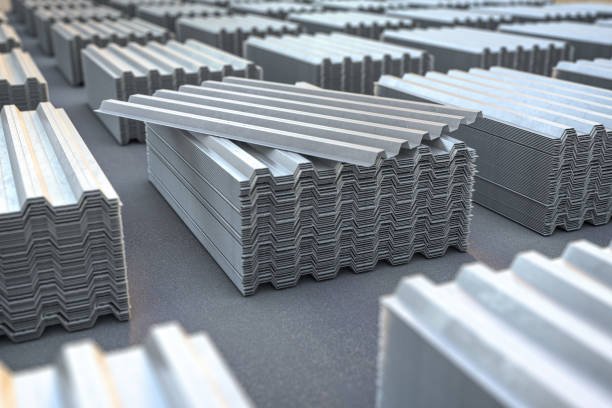

- Roofing Sheets: Many industrial roofs are made of galvanized steel for long-term durability.

- HVAC Ductwork: Galvanizing prevents moisture from corroding the ducts.

- Boat Anchors: Galvanized anchors are more resistant to the corrosive marine environment.

- Garden Tools: Tools like spades and hoes are often galvanized to extend their lifespan.

- Playground Equipment: To withstand outdoor conditions, the metal parts are usually galvanized.

- Wire Mesh and Fencing: Often used in agriculture, these materials are galvanized for durability.

- Handrails: In public transit and buildings, galvanized handrails are common for added safety.

- Ladders: Industrial ladders are often made of galvanized steel for increased strength and corrosion resistance.

- Electrical Conduits: These tubes that house electrical wires are often galvanized.

- Nails and Screws: Galvanized nails and screws are preferred for outdoor construction projects.

- Agricultural Silos: Galvanized steel is often used to construct silos for storing grain.

- Transmission Towers: The structural steel used in electricity pylons is often galvanized.

- Scaffolding: Construction scaffolds are galvanized to ensure they are safe and durable.

Each of these products benefits from galvanization or electro-galvanization processes that improve their corrosion resistance and enhance their durability. These treatments are vital in environments where products are exposed to weather, moisture, or other corrosive elements.