Title: The Importance of Proper Sheave Wheel Placement on the Head Frame: Ensuring Operational Efficiency and Safety

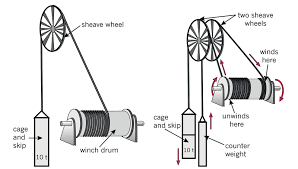

In mining operations, the head frame, also known as the gallows frame, is a crucial component of the infrastructure. One of the key elements of the head frame is the sheave wheel, a large pulley used in conjunction with hoisting ropes to raise and lower conveyances within the mine shaft. Proper placement of the sheave wheel on the head frame is essential for several reasons, chiefly to ensure operational efficiency, safety, and longevity of equipment.

Why is it Important to Place the Sheave Wheel in the Right Place on the Headframe

It is important to place the sheave wheel in the right place on the head frame because it ensures operational efficiency, safety, and longevity of equipment in mining operations. Proper positioning allows for balanced and efficient load distribution during hoisting, reducing delays in material and personnel transportation. From a safety perspective, correct sheave wheel placement minimizes strain on the hoisting ropes, decreasing the risk of rope failure which could lead to catastrophic accidents. Additionally, it reduces uneven wear and tear on both the sheave wheel and hoisting ropes, lowering maintenance needs, enhancing equipment longevity, and resulting in significant cost savings. Thus, proper sheave wheel placement plays a crucial role in maintaining smooth and safe mining operations.

Ensuring Operational Efficiency

The sheave wheel must be correctly positioned to allow for efficient and balanced load distribution during hoisting operations. If it’s improperly placed, it could lead to inefficient hoisting, causing unnecessary delays in the transportation of miners and materials in and out of the mine shaft. The correct positioning of the sheave wheel also minimizes wear and tear on the hoisting ropes, thereby reducing the need for frequent replacements and improving overall operational efficiency.

Safety Considerations

Safety is paramount in any mining operation. Misplacement of the sheave wheel can lead to unequal distribution of loads, which could increase the strain on the hoisting ropes and risk of rope failure. This failure could have catastrophic consequences, including injury or loss of life, as well as significant damage to the mine shaft and equipment. Therefore, correct sheave wheel placement is crucial to ensuring the safety of the workers and the operation as a whole.

Longevity of Equipment

Correct placement of the sheave wheel can extend the lifespan of the mining equipment. When the wheel is properly positioned, it minimizes uneven wear on the hoisting ropes and the wheel itself, thus reducing maintenance needs and enhancing the longevity of the equipment. This reduction in maintenance can translate into significant cost savings over the long term.

Conclusion

The proper placement of the sheave wheel on the head frame is not just a minor detail but a matter of operational efficiency, safety, and cost-effectiveness. Ensuring the correct positioning is crucial to maintaining smooth and efficient hoisting operations, minimizing the risk of equipment failure and associated safety risks, and prolonging the lifespan of critical mining equipment. Therefore, attention to this detail plays a significant role in successful and safe mining operations.